Industry-news

T-FR Type Container Lock Eagle Beak Lock

T-FR Type Container Lock Eagle Beak Lock

Once containers are loaded onto railway flatcars, they need to be secured with locking devices. This ensures that the containers will not fall off the flatcars during train operation. Currently, the most advanced container locking device in China's railways is the T-FR lock. Before 2007, Chinese railways applied cam locks for containers.

Although this type of cam lock structure is widely used worldwide, due to the long and complex railway lines in China, containers fallen frequently during transportation, posing a significant challenge to railway safety. Therefore, railway departments have to reinforce containers with wire during transport, cutting the wire upon unloading. However, this method is inefficient and incurs substantial wire wear and labor costs. To solve this issue, Chinese railway authorities developed a new container locking device, F-TR lock. Because the F-TR lock offers strong locking capabilities and consists of only one component, it requires minimal or no maintenance. Therefore, newly manufactured container flatcars now primarily use the F-TR lock, and older container flatcars are also being gradually converted to use F-TR locks.

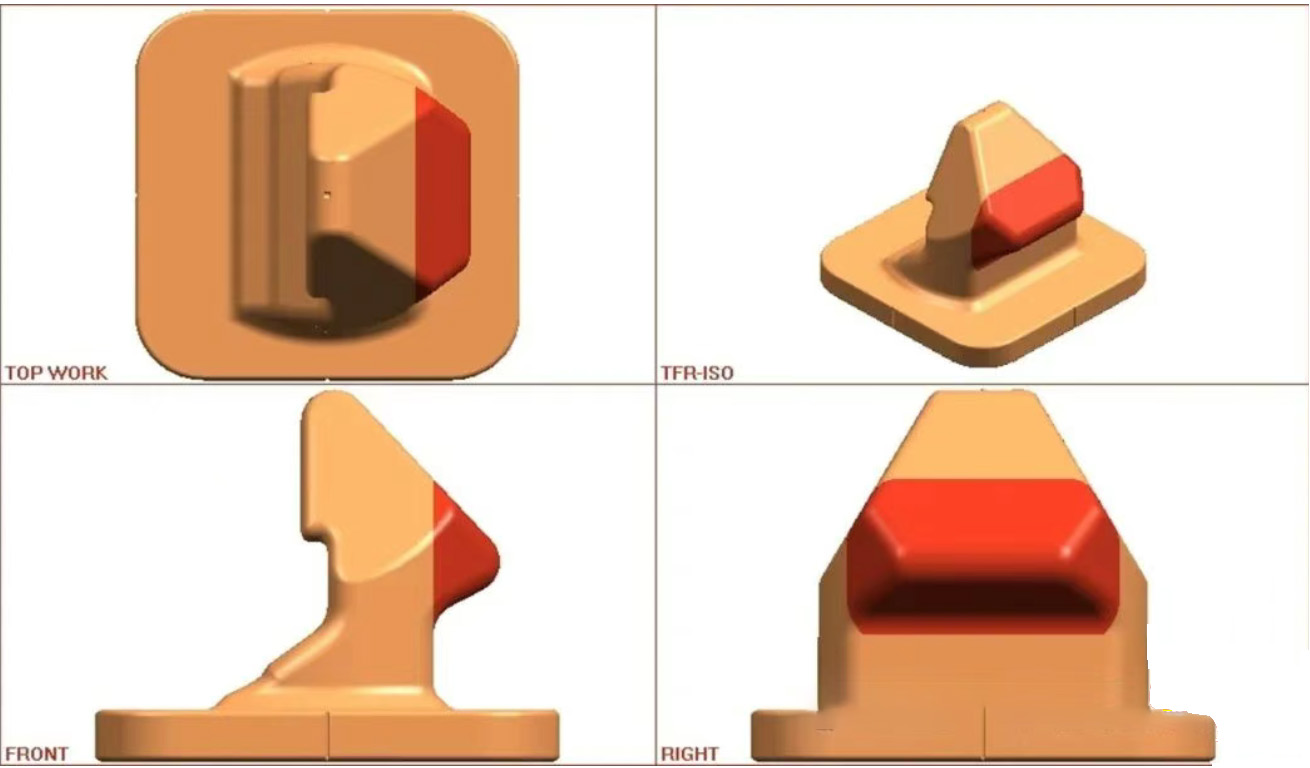

The F-TR lock is also known as the eagle beak lock because its shape resembles an eagle's beak.

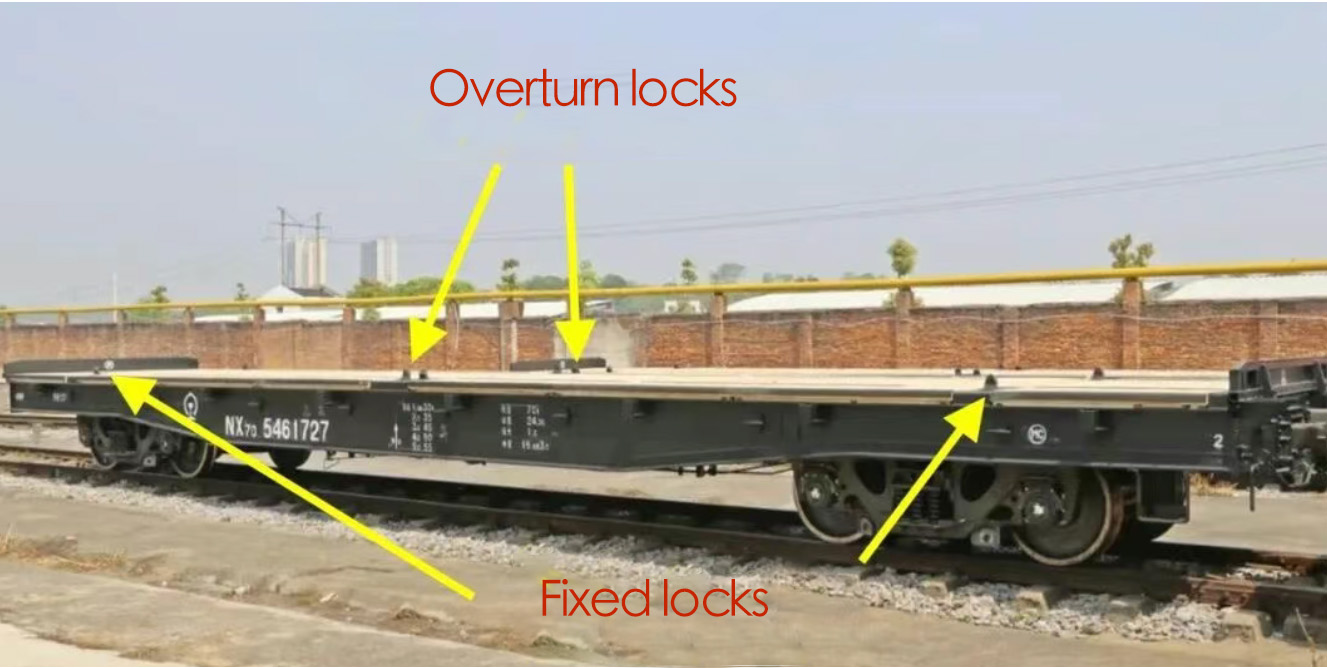

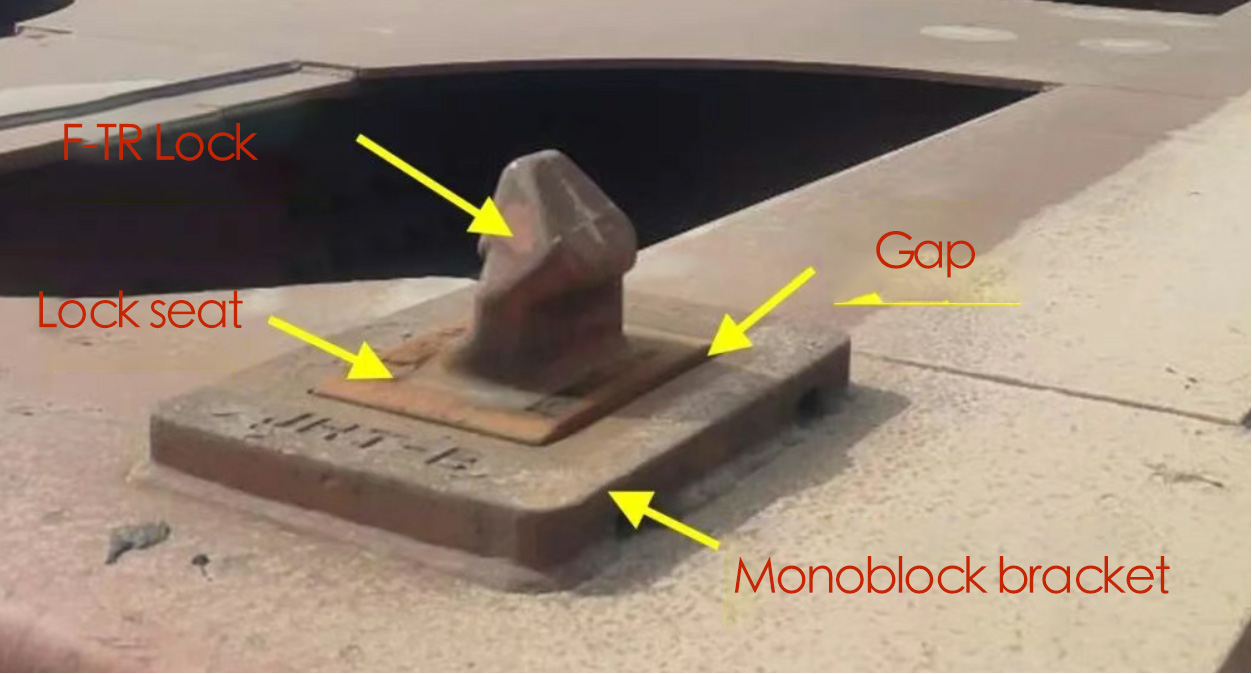

As shown in the diagram, each flatcar is equipped with eight F-TR locks: four fixed locks at the four corners of the car body and four in-situ flip-type locks in the middle. This allows the flatcar to carry either one 40-foot container or two 20-foot containers. The fixed locking device utilizes an integral frame structure, which secures the F-TR locks. A small gap is left on each side between the integral frame and the F-TR lock base, allowing for slight free movement to prevent jamming during loading and unloading operations.

The central in-situ flip lock can be flipped to accommodate different working conditions when loading 20-foot and 40-foot containers.

When loading a 40-foot container, the center tipping lock is in the non-operating position.

When two 20-foot tanks are loaded, the center lock flips up, placing the tank in the working position.

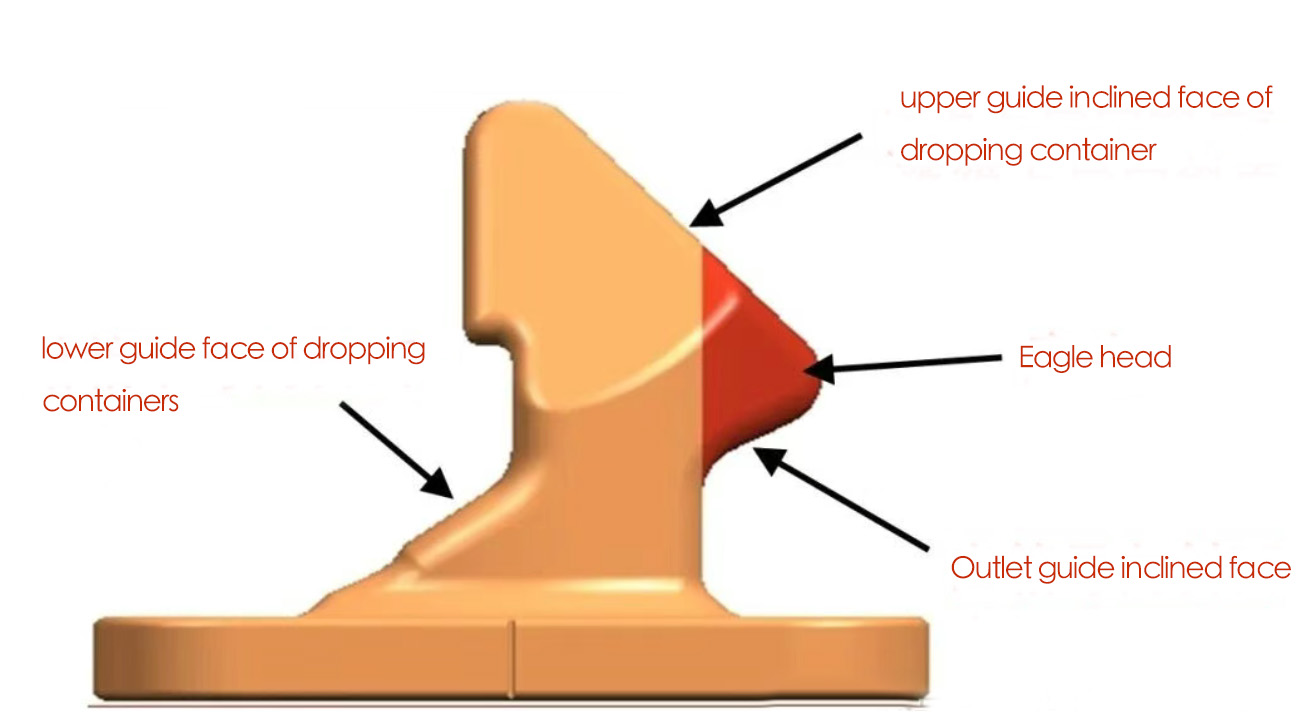

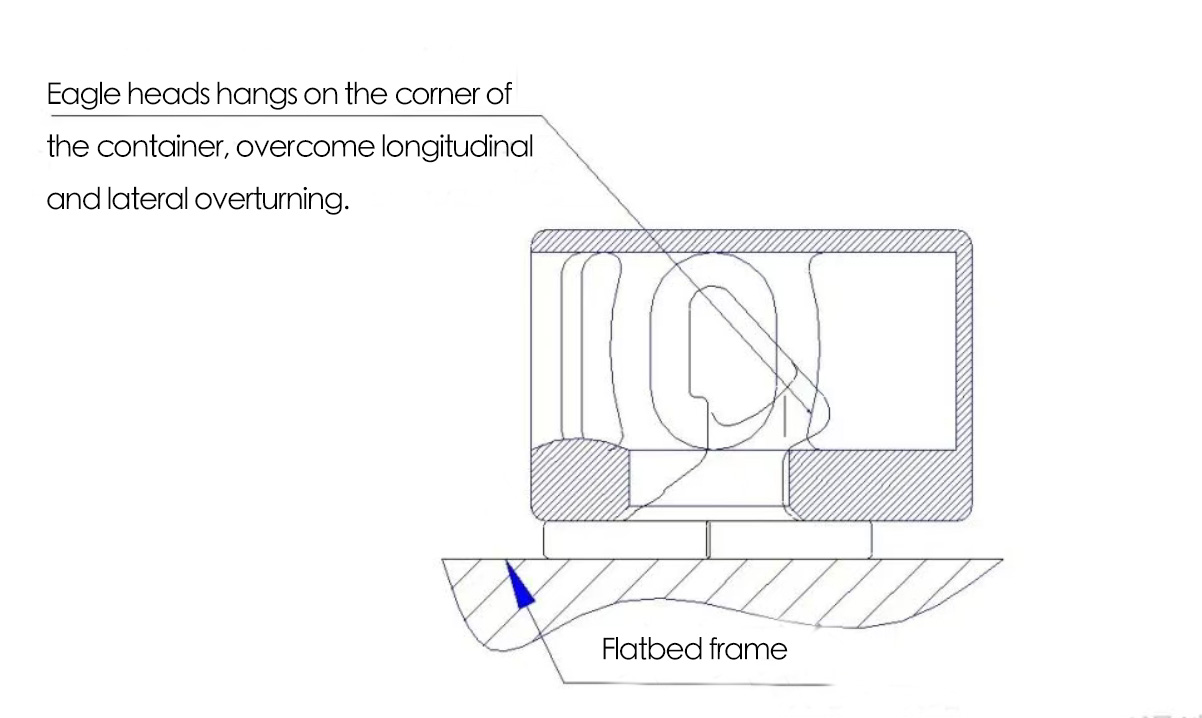

The F-TR lock has three operating surfaces: the upper guide ramp for dropping the container, the guide ramp for exiting the container, and the lower guide ramp for dropping the container. The eagle head structure is responsible for hooking the corner fittings of the container, locking the container, and preventing it from tipping over or jumping up during vehicle operation.

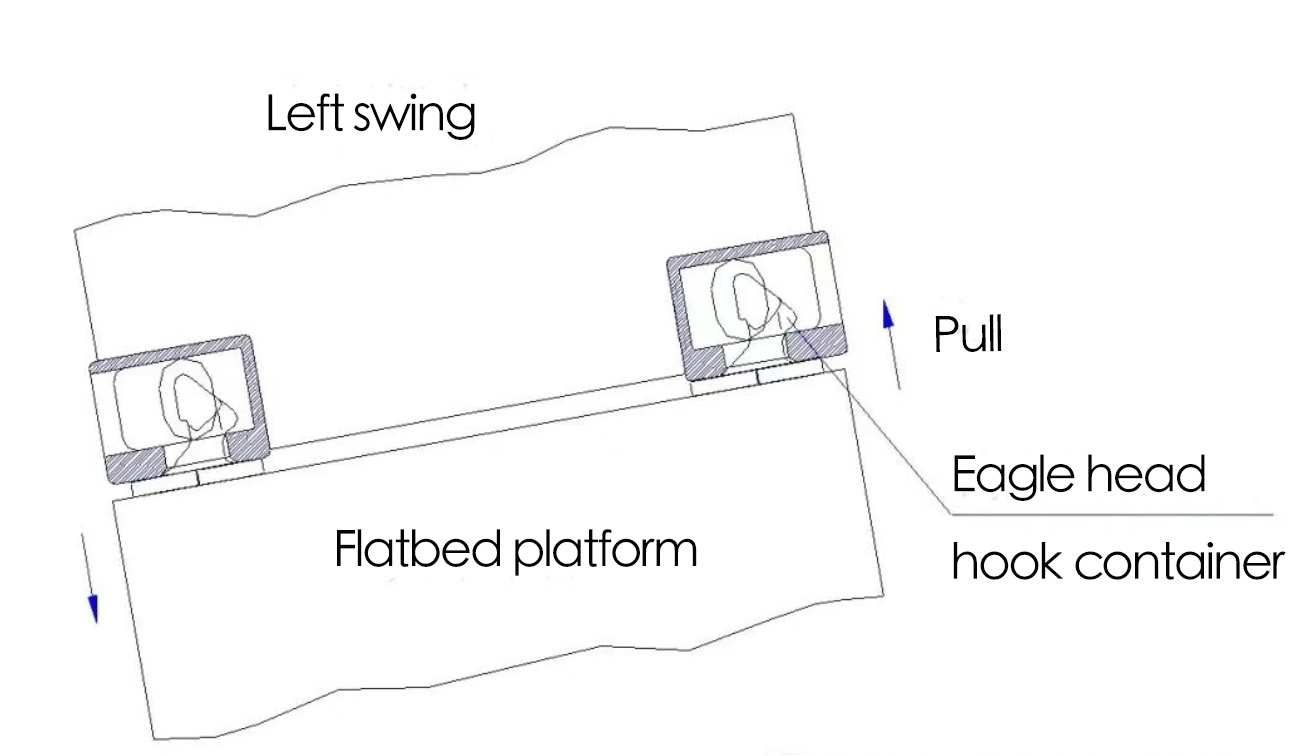

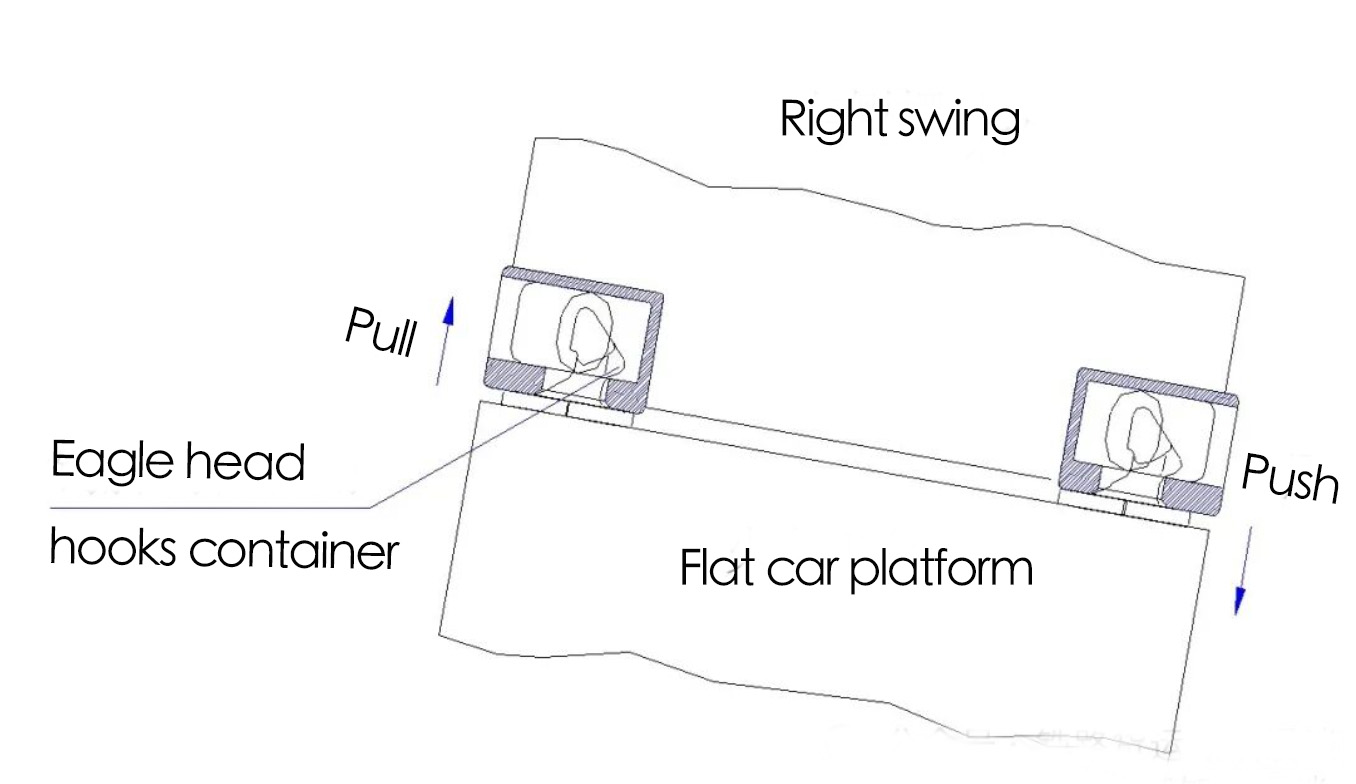

When the container is affected by wind or inertia and swings to the left, the eagle's head will hook onto the corner of the container; when the container swings to the right, the eagle's head will also hook onto the corner of the container.

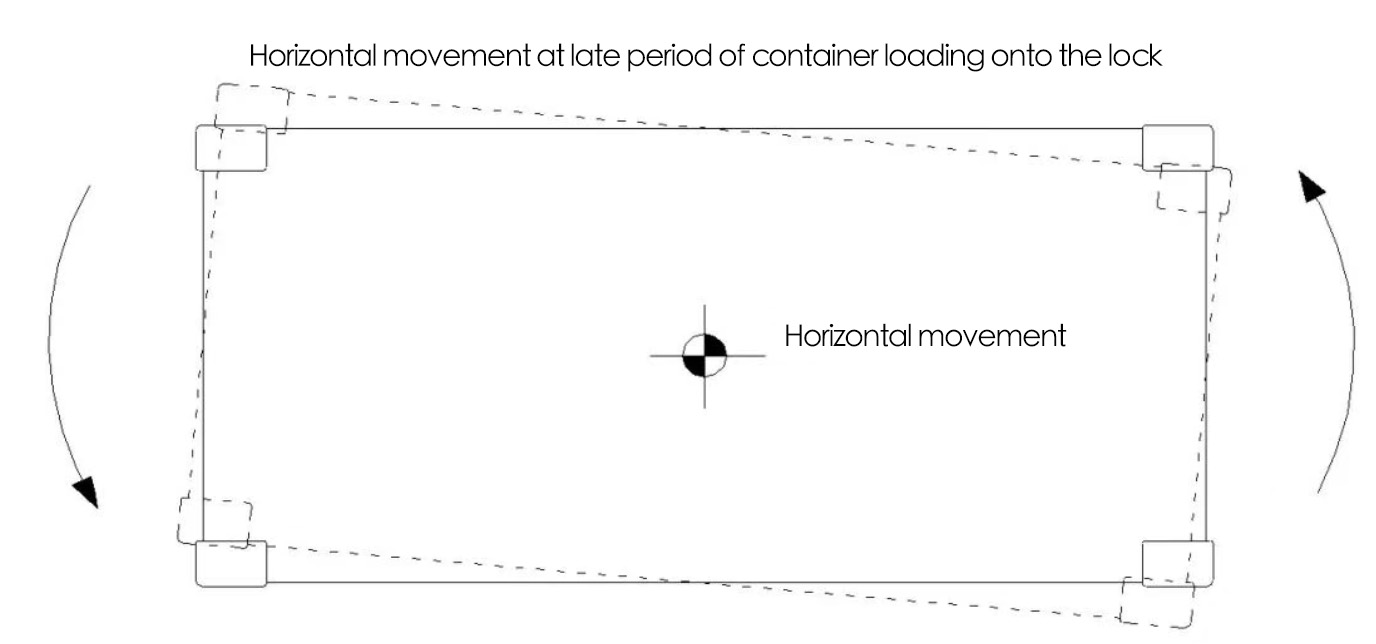

When the container is being loaded, the container corner fitting first slides to one side along the upper guide ramp of the container drop and then slides in the opposite direction along the lower guide ramp of the container drop, so that the container corner fitting is locked under the eagle head of the F-TR type lock.

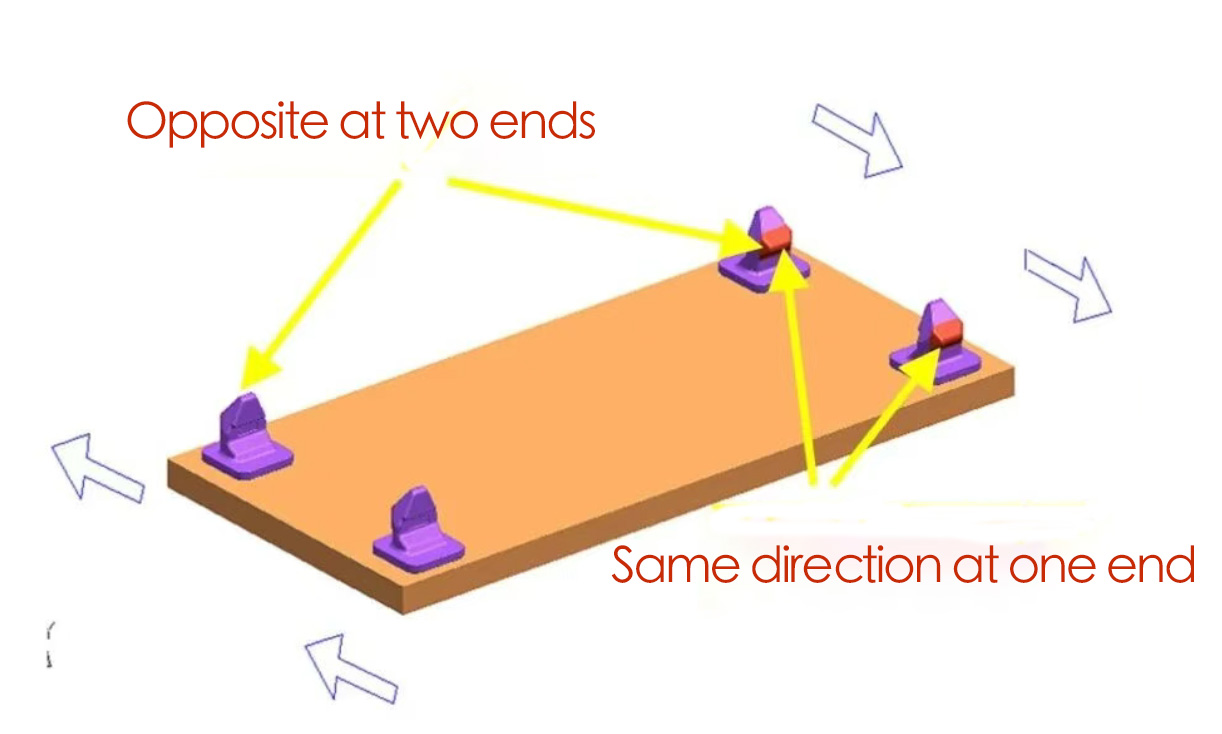

When the container is lifted, the container corner fittings slide out along the guide ramp. To ensure that the F-TR locks function properly, when arranging four F-TR locks on one container, the eagle heads should be aligned in the same direction at the same end and in opposite directions at both ends. After the container corner fittings are inserted into the eagle head, they rotate counterclockwise (see image below).

Video of overturn of T-FR container lock:

RELATED NEWS

CATEGORIES

CONTACT US

Name: Yolanda Zhang

Mobile:+86-18625131201

Tel:+86-562-2856868

Whatsapp:8618625131201

Email:tltkgd@foxmail.com

Add:No.7 Jingqiao Avenue, Yi'an Economic Development Zone, Tongling City, Anhui Province, China. Zipcode:24431