Combined Dust Collector for Freight Wagon Air Brake System

- Category: Air brake system parts

- Drift diameter:25mm

- Applicable air source: 600Kpa

- Hand torque: 9~20Nm

- Material: Stainless steel or casting iron

Combined Dust Collector for Freight Wagon Air Brake System

1. Brief introductions:

A combined dust collector is placed on the brake branch pipe located in the center of the vehicle. Its purpose is to control the flow between the main brake pipe and the branch pipe while also filtering and eliminating dust from the compressed air that flows into the brake branch pipe. This dust collector is known for its straightforward design, excellent reliability, effective sealing ability, easy maintenance, and low resistance when the block door is opened, making it ideal for train inspections and shunting activities.

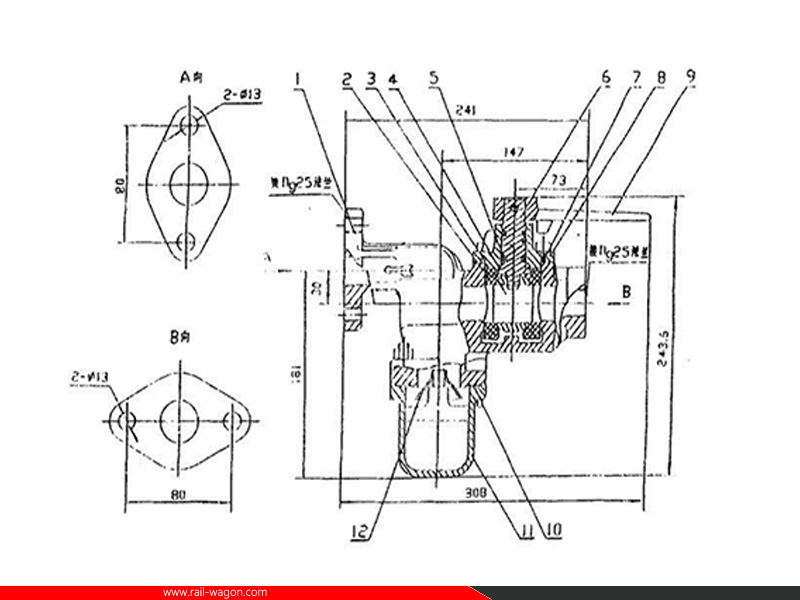

The combined dust collector features a casing, a dust collection component, and a shut-off valve section. This casing includes both an air inlet and an air outlet. Inside the casing, the dust collection component filters the air that moves through the dust collector. The shut-off valve section is also located within the casing and consists of a rotating control mechanism, which is designed to turn within the shell. This mechanism includes a closed position that blocks the flow between the air inlet and outlet and an open position that allows air to pass between them.

2. Technical parameters:

|

Application |

Railway freight wagons |

|

Drift diameter |

25 mm |

|

Applicable air source |

600 kPa |

|

Hand torque |

9~20 Nm |

|

Material |

Stainless steel or casting iron |

|

Working temperature |

-50 ℃ ~ +50 ℃ |

|

Standard |

TB/T 2697 |

3. Application photo:

4. Drawing:

INQUIRY

CATEGORIES

CONTACT US

Name: Yolanda Zhang

Mobile:+86-18625131201

Tel:+86-562-2856868

Whatsapp:8618625131201

Email:tltkgd@foxmail.com

Add:No.7 Jingqiao Avenue, Yi'an Economic Development Zone, Tongling City, Anhui Province, China. Zipcode:24431