Cut Out Cock DN 8 to 32 Casting Iron or Stainless Steel Railway Air Brake Parts

- Category: Air brake system parts

- Nominal diameter: 8-32 mm

- Operation type: Parallel open, vertical closing

- Max. working pressure: 900 KPa(locomotive), 600 KPa(freight car)

- Valve body material: Casting iron or stainless steel

Cut Out Cock DN 8 to 32 Casting Iron or Stainless Steel Railway Air Brake Parts

1. Brief introductions:

The cutout cock is primarily utilized to manage the flow of air in the braking system of train cars. It is positioned on the brake branch pipe and serves to regulate the air pressure flow between the train pipe and the distribution valve. Under regular conditions, it remains in the open position. However, if there is a brake malfunction, it can be closed to halt the flow of compressed air from the main brake pipe, effectively stopping the brake's function.

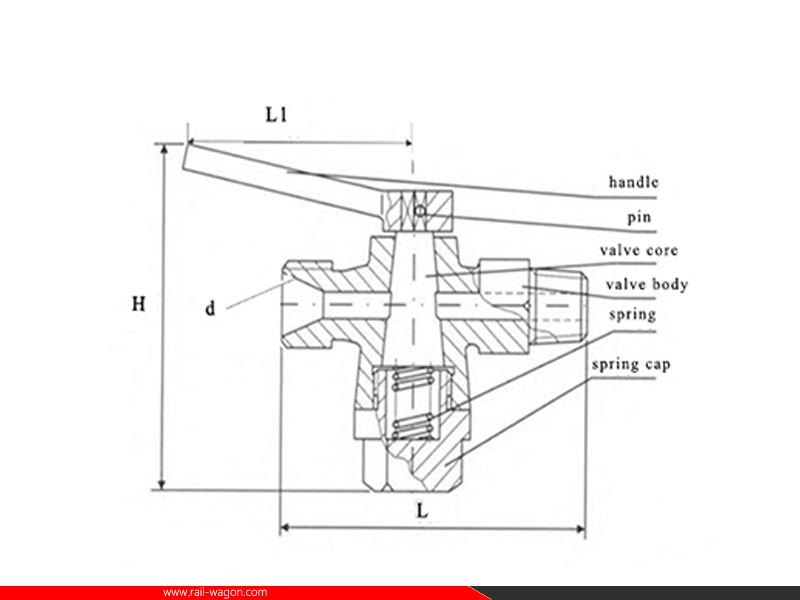

The cut-out cock consists primarily of several components: the valve body, valve core, spring, spring cap, pin, and handle. The valve body is made from gray cast iron (HT200), while the valve core is crafted from Tin Bronze (ZcuSn2Zn11Pb4). The sealing mechanism between the valve body and core relies on a 1:7 conical face fit. In the middle section of the cone, there are circular holes that serve as channels for the pipeline. To open and close the cock, the handle is used to move the valve core between two designated limit positions.

2. Main technical parameters:

|

Name |

Air Brake Parts Ball Type Angle Cock for Locomotive Rail Wagons |

|

Application |

Locomotive, freight wagons |

|

Nominal diameter |

8-32 mm |

|

Operation type |

Parallel open, vertical closing |

|

Max. working pressure |

900 KPa(locomotive), 600 KPa(freight car) |

|

Test before exwork |

Air leakage test |

|

Valve body material |

Casting iron or stainless steel |

|

Working temperature |

-50 ℃ ~ +50 ℃ |

3. Drawing:

INQUIRY

CATEGORIES

CONTACT US

Name: Yolanda Zhang

Mobile:+86-18625131201

Tel:+86-562-2856868

Whatsapp:8618625131201

Email:tltkgd@foxmail.com

Add:No.7 Jingqiao Avenue, Yi'an Economic Development Zone, Tongling City, Anhui Province, China. Zipcode:24431