Train Wheels/Wagon Wheels/Railway Wheels Diameter 650~1300mm AAR EN BS GOST TB Standards

- Category: Bogie Parts

- Application: railway freight wagons/locomotives

- Wheel diameter: 650~1300mm

- Production process: forging or casting

- Materials options: AAR, EN, BS, JIS, GOST, TB

Train Wheels/Wagon Wheels/Railway Wheels Diameter 650~1300mm AAR EN BS GOST TB Standards

1. Brief introduction:

Train wheels are direct contact parts between railway vehicles and railway. It bears the running weight and power transmission of the train vehicle. The wheel thread adopts a conical design, achieving anti derailment function through the engagement of the wheel rim and the steel rail, and achieving turning guidance through the diameter differences on wheel thread.

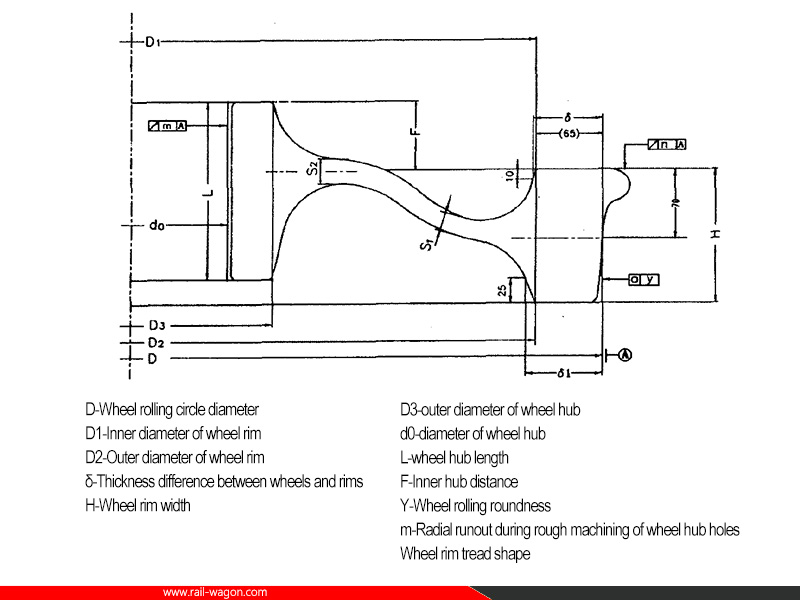

2. Main structure and dimensions:

Train wheels are generally composed of wheel rims, thread, web, and hubs. The wheel rim is located on the outer side of the wheel and is used to withstand the longitudinal force between the wheel and rail, ensuring the stability of train operation. Threads are the outer surfaces of the wheel, used to contact the track and provide traction and braking force to the train through friction. The webs connect the wheel rim and hub, serving as a connection and support. The hub is the central part of a wheel, used for installation on the axle and transmitting power.

The wheels dimension is generally determined based on the requirements of the vehicle and track, mainly including wheel diameter, wheel width, tire thickness, wheel rim height, etc. The size of wheels on different types of trains may vary. Generally, wheels with larger diameters are suitable for high-speed trains, while wheels with smaller diameters are suitable for freight and short distance passenger trains.

The dimension ranges we offer:

|

Outside Diameter Ø D, mm |

Inside Diameter Ø D1, ØD2 mm |

Width of Rim H mm |

Diameter of Hub Ø d mm |

Height of hub L mm |

Diameter of Hole in Hub Ød0 mm |

Thickness of Disk t1, t2 mm |

Mass WG kg |

|

650-1269 |

600-1100 |

95-160 |

185-500 |

90-405 |

60-200 |

15-80 |

165-1050 |

3. Wheels maintenance:

Due to prolonged operation and stress, train wheels are prone to wear and cracking. In order to ensure the safety and efficiency of train operation, it is necessary to regularly maintain and replace the train wheels.

The maintenance work mainly includes wheel surface repair, wheel rim grinding and polishing, and wheel inspection. Wheel surface finishing refers to the restoration of the flatness and smoothness of the wheel surface through mechanical processing or grinding, and the improvement of the contact quality between the wheel and the rail. Wheel rim grinding and polishing refers to the use of special devices to repair the wheel rim, remove cracks and wear on the rim, and extend the service life of the wheel. Wheel inspection refers to the visual and testing methods used to inspect wheels, identify defects and malfunctions, and replace them in a timely manner.

4. The wheels standards:

AAR-M-107/M-208 wheels, carbon steel specification

• EN 13262 railway applications wheels - product requirements

• BS 5892-3 specification for monobloc wheels for traction and trailing stock

• JIS e5402-2 railway rolling stock-solid steel wheel

• TB/T 2817 technical specification of wrought steel solid wheel for railway freight car

5. Quality inspection reports including:

Chemical composition, physical properties, Dimension report, Microstructure, Macrostructure, Nonmetallic inclusions, Ultrasonic testing, Magnetic particle testing, Residual stress, Static balance.

6. Drawings:

7. Package:

4pcs/pallet or 6pcs/pallet

INQUIRY

CATEGORIES

CONTACT US

Name: Yolanda Zhang

Mobile:+86-18625131201

Tel:+86-562-2856868

Whatsapp:8618625131201

Email:tltkgd@foxmail.com

Add:No.7 Jingqiao Avenue, Yi'an Economic Development Zone, Tongling City, Anhui Province, China. Zipcode:24431