8 Inch / 10 Inch / 12 Inch / 14 Inch Air Brake Cylinder Railway Locomotive / Wagons

- Category: Air brake system parts

- Sizes:8’’ , 10’’ , 12’’ , 14’’

- Max. Stroke: 254mm

- Manufacture process: Spinning formed

- Applicable max. air pressure: 600kPa

8 Inch / 10 Inch / 12 Inch / 14 Inch Air Brake Cylinder Railway Locomotive / Wagons

1. Brief introductions:

The brake cylinder plays a crucial role in the air brake system of railways, significantly impacting the safety of railway vehicles in operation.

This cylinder generates a push force based on the changes in air pressure and the size of its piston. The generated push force is conveyed directly to the brake rigging device using the piston rod of the cylinder. Subsequently, the brake rigging transmits this force to the brake shoes or pads, which make contact with the wheel treads, thereby initiating the braking process. When the train needs to stop braking, a device attached to the push rod of the brake cylinder pulls the brake rigging back, allowing the brake shoes to disengage from the wheel treads.

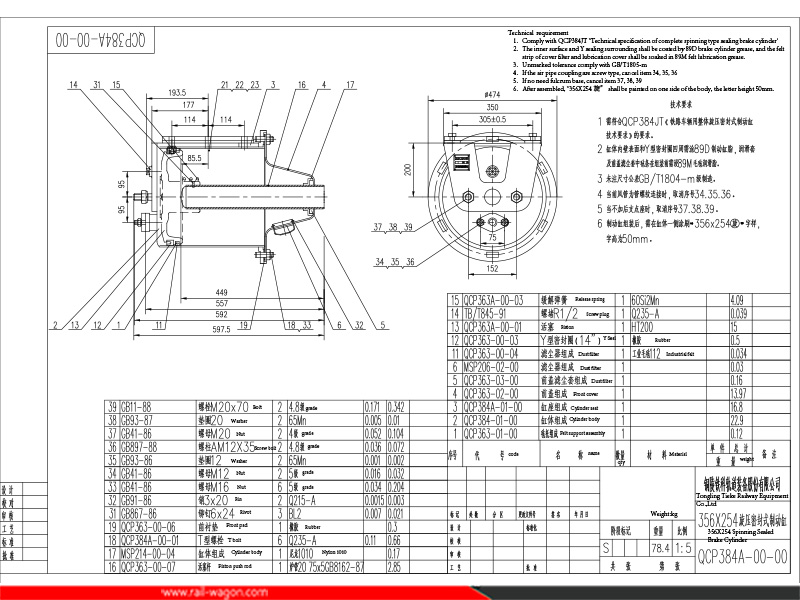

Air brake cylinders used for locomotives or railway cars are categorized by their internal diameter into sizes of 14", 12", 10", and 8". The piston rod has a full stroke of 254 mm. Key components of the cylinder include the body, Y-shaped sealing ring, lubricating sleeve, piston, piston rod, recovery spring, brake cylinder cap assembly, and front cap filter. The cylinder body is crafted from high-quality carbon steel using a spinning process, leading to a lightweight design with a straightforward construction and dependable performance.

2. Technical parameters:

|

Application |

Air brake system for locomotive and railway wagons |

|

Inner diameter |

8’’ , 10’’ , 12’’ , 14’’ |

|

Max. stoke |

254 mm |

|

Working temperature |

-50 ℃~+70 ℃ |

|

Cylinder body manufacture process |

Spinning formed |

|

Sealing ring type |

Y shape |

|

Lubricating grease |

89D brake cylinder grease |

|

Applicable max. air pressure |

600 kPa |

|

Quality assured tests |

Piston movement test at 80 kPa; Air pressure leakage test at 600 kPa |

3. Packing photos:

4. Drawing:

INQUIRY

CATEGORIES

CONTACT US

Name: Yolanda Zhang

Mobile:+86-18625131201

Tel:+86-562-2856868

Whatsapp:8618625131201

Email:tltkgd@foxmail.com

Add:No.7 Jingqiao Avenue, Yi'an Economic Development Zone, Tongling City, Anhui Province, China. Zipcode:24431