Railway Ammonia Tank Wagon Broad Gauge 1520mm Gauge Tanker Car

- Category: Railway tank wagon

- Pay load: 50t

- Max. allowable working pressure: 2.2 MPa

- Efficient volume: 80 m³

- Rail gauge:1520mm

Railway Ammonia Tank Wagon Broad Gauge 1520mm Gauge Tanker Car

1. Brief introduction

This ammonia tank wagon is used to transport liquid ammonia by 1520mm gauge railway line. The pay load is 55t and the efficient volume is 80m³.

2. Main technical parameters:

|

Max. Pay load |

≥50.14t |

|

Max. allowable working pressure |

2.2MPa |

|

Design pressure |

2.2MPa |

|

Air tight test pressure |

2.2MPa |

|

Max. allowable external pressure |

0.1MPa |

|

Max. volume |

87m³ |

|

Efficient volume |

80m³ |

|

Working temperature |

-40℃~50℃ |

|

Design temperature |

50℃ |

|

MDMT |

-40℃ |

|

Wave Preventer |

No |

|

Max. total weight |

86 t |

|

Axle load |

25 t |

|

Design speed |

120 km/h |

|

Min radius |

120 m |

|

Dimension |

12020*3240*5010mm |

|

Rail gauge |

1520 mm |

|

Limit gauge |

ГОСТ 9238-83 1-T |

|

Loading method |

Top load, top unload |

3. Main Structure:

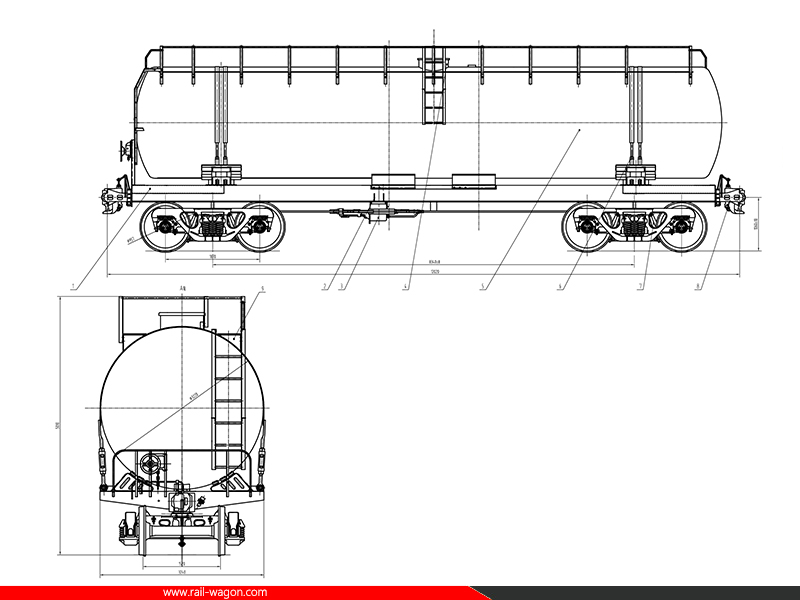

The ammonia tank wagon is mainly composed of tank, chassis, brake device, coupler & draft gear device, bogies, etc.

3.1 Chassis

The chassis is mainly assembly welded of traction beams, lower side beams, sleeper beams, crossbeams, end beams, etc. The traction beam is made of hot-rolled 310B steel with a yield strength of 450MPa; The lower side beam is assembly welded by cold-formed square tubes, cold-formed channel steel, and cold-formed angle steel; The sleeper beam is assembly welded of upper and lower cover plates and double web plates to form a variable cross-section box structure; Steel flooring is laid on both ends of the chassis outside the sleeper beam. The chassis is equipped with a saddle and a tank connecting plate in the middle for fixing the tank. There are stoppers at both ends of the chassis. The main materials used for manufacturing the chassis are Q450NQR1, 09CuPCrNi-A, and Q235A, which comply with Chinese standards.

3.2 Tank

The tank body is mainly composed of a head, a cylinder, a manhole, valve components, anti wave plates, etc. The main material of the tank body is 16MnDR pressure vessel special plate, which meets the standards of the Chinese pressure vessel industry. The diameter of the tank body is 3100mm, the nominal thickness of the cylinder plate is 24mm, and the nominal thickness of the head is 26mm. There is a 500mm diameter manhole at the top of the tank. There is one DN80 safety valve installed at the top of the tank, with a set pressure of 2.49MPa. The remaining valve components are concentrated in the manhole cover protective cover, mainly including one DN50 gas-phase emergency shut-off valve, one DN80 liquid-phase emergency shut-off valve, one level gauge, and one pressure gauge.

3.3 Brake device

The air brake system meets the requirements of Russian standards and consists of a 483A three-way valve, a 265A-1 automatic adjusting valve, a RTRP-300 brake shoe clearance automatic adjuster, an RT7-78 air storage cylinder, a 508B brake cylinder that meets the requirements of GOST R5392, 4370 connectors, 4371 connectors, 4379 connectors that meet the requirements of TU 3184-011-10785350-2007, a 4314B angled plug, a 4300V cut-off plug and a 4316U1 valve plug, and a P17B brake hose that meets the requirements of GOST 2593. It adopts NSW type (high-power) manual brake to meet the requirement of parking on a 30 ‰ slope when the vehicle is fully loaded.

3.4 Coupler & draft gear assembly

The coupler & draft gear device consists of СА-3 type coupler, MT-2 type buffer, CA-3 type yoke, follower plate, coupler lifting rod, support beam, suspension rod and yoke support plate, etc.

3.5 Bogie

The tank car uses 1520mm rail gauge broad-gauge bogie. The bogie adopts two-stage stiffness spring; a lower center plate with a diameter of φ355mm, and a conductive center plate wear plate installed in the lower center plate; 353130B compact bearings approved by Document No.21 The Transportation and Loading Truck (2006) ;LZ50 steel axles and 957mm wheel; the basic brake device adopts the Austenitic-Bayer ductile iron bushing and combined brake beam.

4. Drawing:

5. Application photo:

INQUIRY

CATEGORIES

CONTACT US

Name: Yolanda Zhang

Mobile:+86-18625131201

Tel:+86-562-2856868

Whatsapp:8618625131201

Email:tltkgd@foxmail.com

Add:No.7 Jingqiao Avenue, Yi'an Economic Development Zone, Tongling City, Anhui Province, China. Zipcode:24431