Rotary Coupler No.16 Coupler Interlocking Railway Open Wagons Coupler Hook

- Category: Coupler & Draft Gear

- Model: No.16

- Application: 70T open wagons unloaded by dumper

- Material: grade E casting steel

- Compatible: No.13, No.17, AAR couplers

Rotary Coupler No.16 Coupler Interlocking Railway Open Wagons Coupler Hook

1. Brief introduction

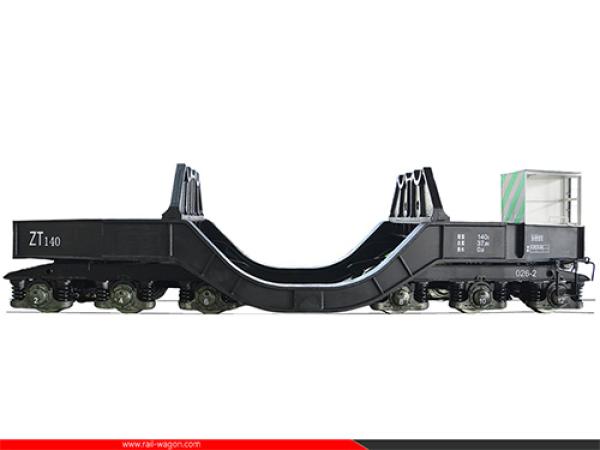

No.16 coupler is the key connecting parts between railway vehicles. It is mainly applied for 70t coal open wagons, which are unloaded by dumper machines, realizing unloading without decoupling the wagons.

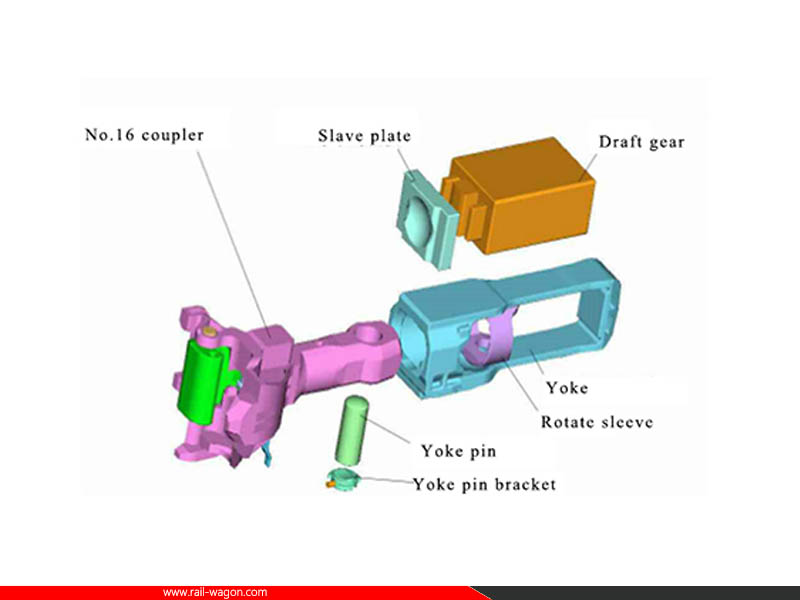

No.16 coupler is reasonably designed, made of E-grade steel, with high structural strength and good mechanical properties. The No.16 coupler is used in conjunction with the No.16 coupler yoke to achieve rotation function, realizing the vehicle to perform continuous turnover and unloading operations without decoupling. It adopts AAR S117-67 ‘F type interlock coupler profile’. It is with strong adaptability and could be connected with No.13 coupler, No.17 couplers and AAR couplers.

2. Main technical features of No.16 coupler:

- The No. 16 coupler can be connected to the 13B coupler, 17 coupler, AAR E coupler, AAR E/F coupler, and AAR F coupler.

- Constructed from Grade E high-strength, low-alloy steel, the No. 16 coupler has minimum static tensile failure loads of 4005 kN for the coupler body and 3430 kN for the coupler knuckle.

- The profiles of closed couplers have a free clearance of 9.5 mm, which reduces longitudinal impact while the train is in motion, enhancing its dynamic performance.

- The No. 16 couplers meet the TB/T 456 standard regarding 'Automatic coupler buffer devices for vehicles with couplers.'

- An interlocking mechanism on the coupler head allows for automatic centering once coupled. This feature minimizes wear on both the coupler body and knuckle while improving their stress conditions and extending their lifespan. Moreover, it helps maintain vertical alignment after coupling, aids in transferring the torsional moment of the tipper, and enhances the coupler’s rotational capabilities.

- With an approximately circular end surface, the No. 16 coupler lessens rotation resistance between the coupler body and the support seat. The contact area between the coupler yoke and slave plate is designed to be spherical, allowing for 360° rotation around the car body's longitudinal centerline. This design enables efficient unloading of the wagon without the need to detach the couplers (only the dumper needs to be turned), greatly boosting unloading efficiency.

3. Main technical parameters:

|

Coupler contact profile |

Comply with AAR S117-67 ‘F Type Interlock coupler profile’ or TB/T2950-1999 ‘Interlock coupler connect profile’ |

|

Longitudinal movement clearance of coupler connecting profile |

9.5mm |

|

Maximum lateral swing angle of coupler |

13° |

|

Maximum vertical swing angle of coupler |

Upward 5°30’, downward 7° |

|

Maximum lateral displacement at coupler connecting line |

167mm |

|

Maximum relative angle in horizontal plane |

3°45′ |

|

Maximum angle of vertical plane |

2°0′ |

|

Allowable height difference of coupler centerline when two couplers are connected |

75mm |

|

Coupler body static tensile failure load |

≥4005KN |

|

Coupler knuckle Static tensile failure load |

≥3430KN |

|

Minimum limit load of coupler yoke (including forging) |

≥4005KN |

4. Detail photo:

INQUIRY

CATEGORIES

CONTACT US

Name: Yolanda Zhang

Mobile:+86-18625131201

Tel:+86-562-2856868

Whatsapp:8618625131201

Email:tltkgd@foxmail.com

Add:No.7 Jingqiao Avenue, Yi'an Economic Development Zone, Tongling City, Anhui Province, China. Zipcode:24431