1067mm Gauge Railway Cement Powder Tank Wagons Pay Load 59T

1. Brief introduction

This 1067mm Cape Gauge Railway Tanker is specially designed for transportation of bulk cement powder. The axle load is 20T and the pay load is 59T.

2. Main technical parameters:

|

Load

|

59t

|

|

Tare weight

|

21t

|

|

Volume

|

50 m³

|

|

Commercial running speed

|

100 km/h

|

|

Rail gauge

|

1067mm

|

|

Min radius

|

80m

|

|

Bogie type

|

3 piece casting bogie with 1067mm gauge

|

|

Coupler buffer

|

Chinese No.13 coupler

|

|

Coupler center height

|

850mm

|

|

Wheel diameter

|

840mm

|

|

Limit gauge

|

Customized

|

3. Structure:

The structure of this powder tank wagon mainly consists of traction pillows, tank body assembly, starting ad unloading system, ladder and walkway assembly, brake device, coupler buffer device, and bogie, etc.

The assembly of traction pillows mainly consists of traction beams, sleeper beams, side beams, end beams, and crossbeams welded together. The traction beam is mainly composed of a traction beam, a front auxiliary plate seat, an integral rear auxiliary plate seat, and an upper center plate. The traction beam is made of hot-rolled 310 type B steel, and the front plate seat is connected to the traction beam with rivets. The upper center plate is connected to the lower flange of the traction beam using rivets, and is connected to the integral rear plate seat using countersunk bolts. The sleeper beam adopts a single web side tube support structure, mainly composed of the sleeper beam web plate, sleeper beam lower cover plate, side columns, etc. welded together. The end beam is composed of a web plate and a lower cover plate welded together. The side beams are made of cold-formed channel steel and are equipped with accessories such as footrests, handrails, and towing hooks. The crossbeam is composed of a box shaped structure welded together by crossbeam web plates, crossbeam upper and lower cover plates, and crossbeam cushion plates.

The tank body is mainly composed of welded heads, cylinders, manholes, fluidized beds, ash chutes, etc. The cylinder adopts a straight cone circular cross-section inclined bottom structure, with the bottom sloping downwards from both ends to the middle section, and a standard elliptical head is used. The top of the tank is equipped with 3 open side loading ports that also serve as manholes, the bottom is equipped with ash chutes, and the bottom of the tank is equipped with fluidized beds and side plates. The fluidized bed is mainly composed of fluidized bed support, edge beams, end beams, porous plates, and fluidized fabrics.

-

Pneumatic unloading system

The pneumatic unloading system mainly consists of ball valves, safety valves, pressure gauges, butterfly valves, annular injectors, check valves, inlet ducts, exhaust ducts, and hoses. There are air inlet pipelines at both ends and three locations in the middle of the system, each equipped with an independent control valve, which optimizes the pressure field distribution of the pressure chamber, improves the unloading efficiency and net unloading rate, and reduces the residual amount of goods.

-

Ladder and walkway assembly

The end is equipped with a ladder, and the top of the tank is equipped with a workbench and a protective fence. The height of the railing is 300mm. The workbench is made of steel grating.

The braking device’s main pipe pressure meets 500kPa and 600kPa, mainly composed of a 120 type control valve, a 254mm × 254mm integral spinning sealed brake cylinder, ST2-250 type bidirectional brake shoe clearance automatic adjuster, an empty and heavy vehicle automatic adjustment device allowed to be installed according to the requirements of the transport wagon [2005] No. 80 document, a ball core folding angle cock, a combined dust collector, a braided brake hose assembly, high friction coefficient synthetic brake shoes, flange joint, an O-Bei ductile iron bushing, and supporting round pins and pipe systems. The braking force can meet 80km/h, and the emergency braking stroke is smaller than 700m.

It adopts Chinese NSW hand brake machine, whose hand wheel diameter 400mm, brake ratio is 27. The mounting height could be adjust according to customer requirements.

Adopting Chinese No. 13 automatic bottom acting coupler, matching hook yoke, ST type buffer and alloy steel yoke pin.

The bogie is a three piece cast steel ride control type bogie, which adopts a control type inclined wedge damping device. The main components include wheelset assembly, bolster assembly, side frame assembly, bearing assembly, bearing adapter, foundation braking device, bearing spring, wedge vibration reduction, lower side bearing, and other components. The performance of the bogie meets the evaluation requirements of GB/T5599, and the strength design meets the requirements of TB/T1335.

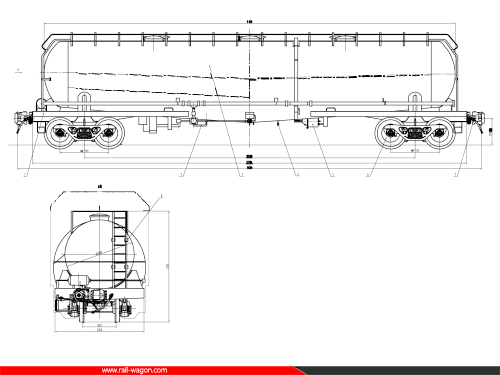

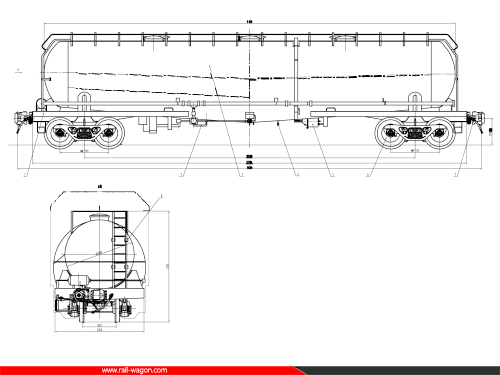

4. Drawing: